Smart Technology

The big difference between Pirontex® and other fabrics is the innovative and environmentally friendly production method that we, together with our textile manufacturer, have decided to adopt in order to create a unique and inimitable product.

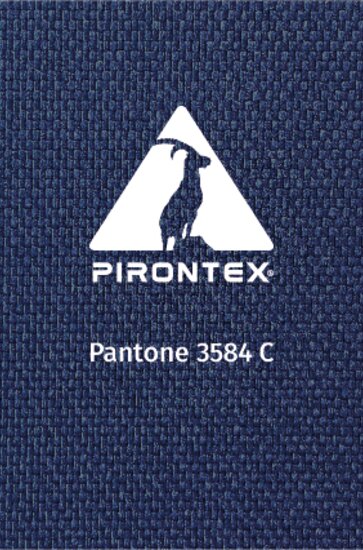

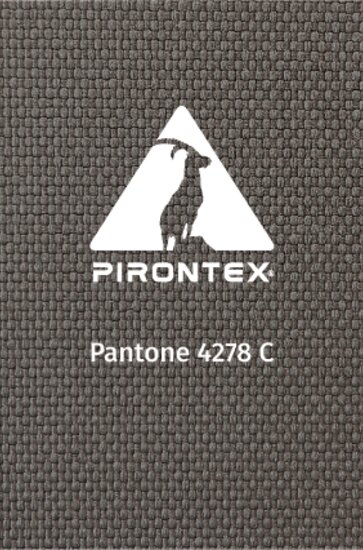

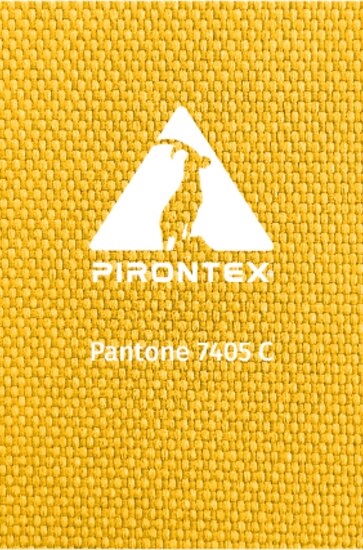

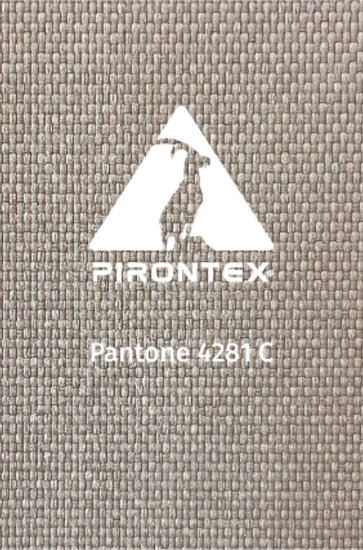

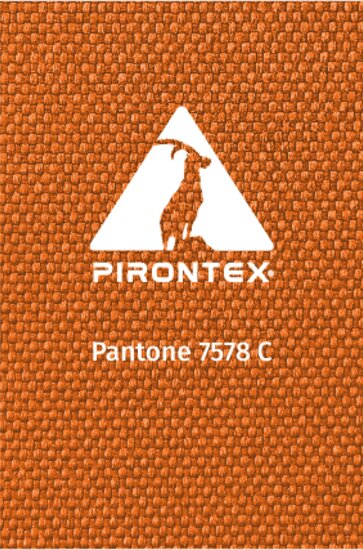

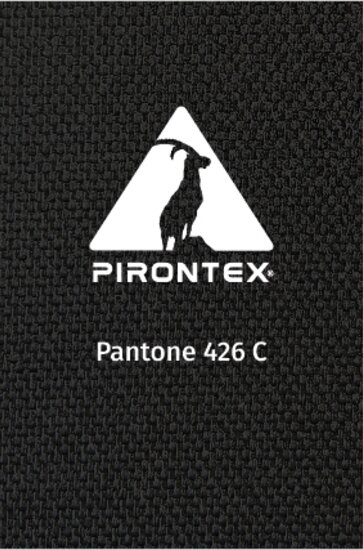

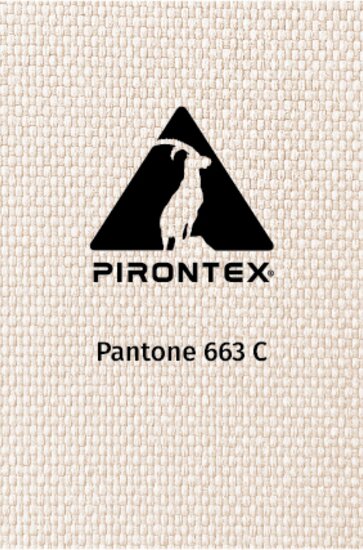

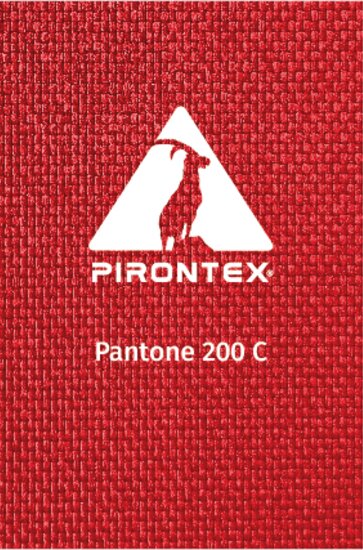

Pirontex® is produced with a mix of new and recycled polyester polymers that are combined with colour pigments before being processed into yarn. This dyeing method is called "solution dyeing" and ensures that the product is not dyed with chemical solutions after its production, but is made from an already coloured yarn.

Why doesn't everyone use the solution dyeing process if it is so advantageous?

Solution dyeing is only feasible when huge quantities of fibre of the same colour are required, which for many companies is not sustainable. Moreover, applying a new dyeing method means a change in machinery and organisation, and many dyeing factories are simply not ready for this.

Common fabrics are made with a mostly greyish thread. The fabric is then dipped into a dye bath to obtain the desired colour.

Other fabrics